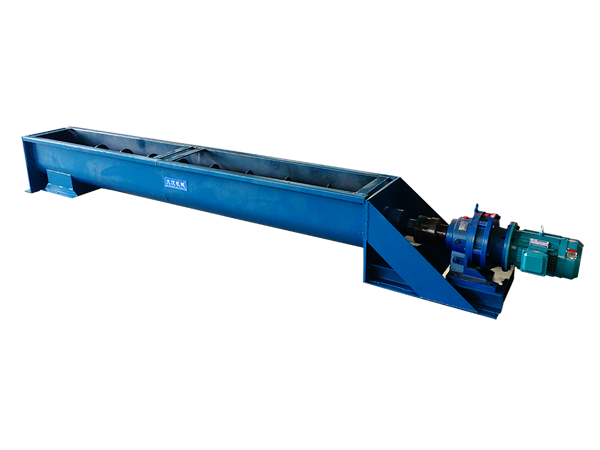

U-Shaped Screw Conveyor

The material conveying is realized by the rotation of the screw shaft in the U-shaped groove, and the intermediate feeding and multi-point feeding can be carried out at different positions, and the intermediate loading and unloading during the conveying process. The material can also be stirred, mixed, heated and cooled during transportation, and the flow rate of the material can be controlled by adjusting the rotational speed

Conveying length: 10-20 meters

Output: 134 m³/h

Slot width: 200-600mm

Inclination: ≤15°

Material: carbon steel/stainless steel

Introduction of U-Shaped Screw Conveyor

U-Shaped Screw Conveyor is a sealed or open U-shaped conveying pipe groove design, which can be used in many fields such as chemistry, food, environmental protection, etc. It can be designed with or without a shaft for conveying fluid or semi-fluid materials .

U-Shaped Screw Conveyor is suitable for horizontal or small inclination angle conveying (inclination angle ≤ 20°), and the conveying work of the material is realized by the screw rotation in the U-shaped groove, the thrust of the material itself and the friction between each other.

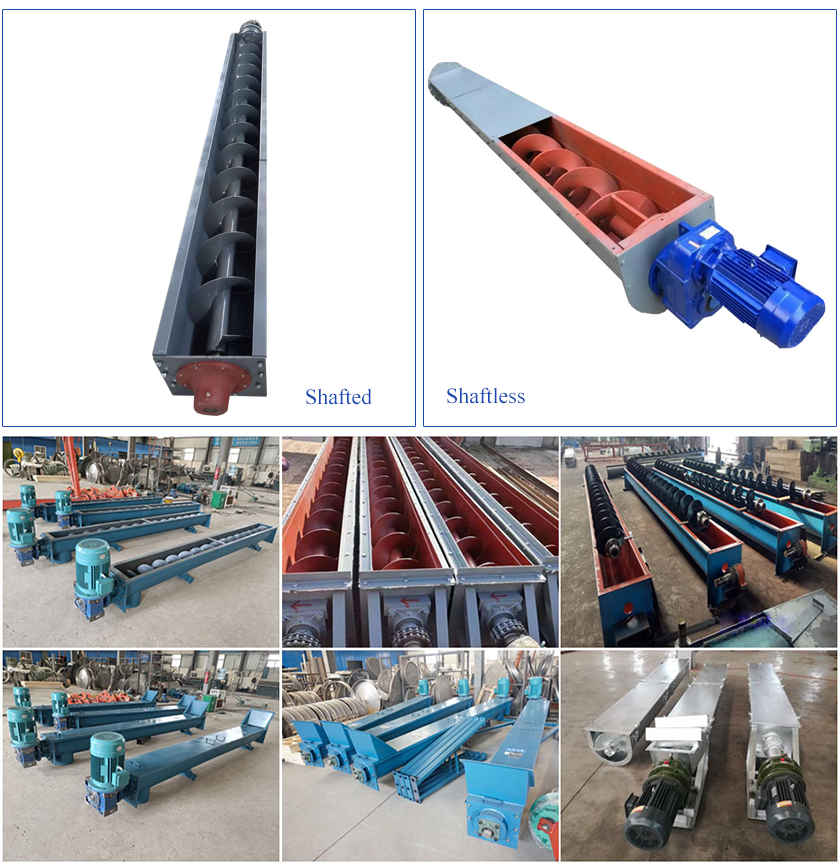

Types of U-Shaped Screw Conveyor

U-shaped shaftless screw conveyor: granular/powder material, wet/paste material, semi-fluid/viscous material, easy to entangle/easy to block material, material with special hygiene requirements.

U-Shaft Screw Conveyor: Materials that are not easy to stick and have certain friction. There are certain requirements for the wear resistance of the screw conveyor.

In addition, carbon steel or stainless steel material can be selected according to the conveying material (stainless steel material is mainly used in industries that have requirements on the conveying environment such as grain, chemical industry, food, etc., with high cleanliness and no pollution to the material.)

Application advantages and limitations of U-Shaped Screw Conveyor

In practice, the U-Shaped Screw Conveyor is often compared to the Tubular Screw Conveyor without even knowing the difference between the two.

Application advantages of U-Shaped Screw Conveyor

The biggest advantage of U-Shaped Screw Conveyor is that under the same space occupancy, compared with the tubular type, the design of the "U" groove can provide a larger material conveying space. The U-Shaped Screw Conveyor has two more cut corners, so the conveying capacity of the U-Shaped Screw Conveyor is about 1.5 times that of the tubular screw conveyor.

U-Shaped Screw Conveyor can be used to transport fluid, semi-fluid and almost non-fluid particles, powder, slurry materials, such as grain, flour, rubber particles, wood chips, sludge, garbage, etc.

In addition, U-Shaped Screw Conveyor's detachable tank cover can be opened at any time, which can facilitate the maintenance of the machine and clean up the remaining materials in the U-shaped tank in time to avoid blockage. Of course, the design of the tank cover enables the U-Shaped Screw Conveyor to design multiple feeding ports on it to match the existing feeding equipment.

Limitations of U-Shaped Screw Conveyor

Most U-Shaped Screw Conveyors are open-type conveying, and some U-Shaped Screw Conveyors are designed with organic covers, but the movable slot cover is clamped on the casing with a cover buckle, and the sealing is relatively poor, and it is only suitable for use at an inclination angle below 20° .

At the same time, the running speed of the U-Shaped Screw Conveyor is relatively slow. When faced with the transportation at a large inclined angle, it will face the problems of insufficient power and slow feeding speed.

Dahan Machinery provides standard U-Shaped Screw Conveyor with screw diameters of 200mm, 250mm, 300mm, 400mm, 500mm, and 600mm, and can also make special designs for the machine according to your actual needs. We have professional designers to provide you with design drawings and full-process services.

Video

The various types of u-shaped screw conveyors produced by Dahan Company are available. If you have special needs, we will design them free of charge according to your actual situation.

Technical Parameters

| Specification | Technical performance | Drive | Drive | Weight (kg) | |||

| Diameter | Length (m) | Output (t/h> | Speed (min) | Reducer | Electric motor | ||

| Model | Speed ratio | Power(kw) | |||||

| U 200 | -10 | 9 | 60 | ZQ250 | 23.34 | 1.1 | 726 |

| U 200 | -20 | 9 | 60 | ZQ250 | 23.34 | 1.5 | 1258 |

| U 250 | -10 | 15.6 | 60 | ZQ250 | 23.34 | 2.2 | 960 |

| U 250 | -20 | 15.6 | 60 | ZQ250 | 23.34 | 3 | 1750 |

| U 300 | -10 | 21.2 | 60 | ZQ350 | 23.34 | 3 | 1373 |

| U 300 | -20 | 21.2 | 60 | ZQ350 | 23.34 | 4 | 2346 |

| U 400 | -10 | 51 | 60 | ZQ400 | 23.34 | 5.5 | 1911 |

| U 400 | -20 | 51 | 60 | ZQ500 | 23.34 | 11 | 2049 |

| U 500 | -10 | 87.5 | 60 | ZQ400 | 23.34 | 7.5 | 2381 |

| U 500 | -20 | 87.5 | 60 | ZQ650 | 23.34 | 18.5 | 5389 |

| U 600 | -10 | 134.2 | 45 | ZQ750 | 23.34 | 22 | 3880 |

| U 600 | -10 | 134.2 | 45 | ZQ850 | 23.34 | 55 | 7090 |

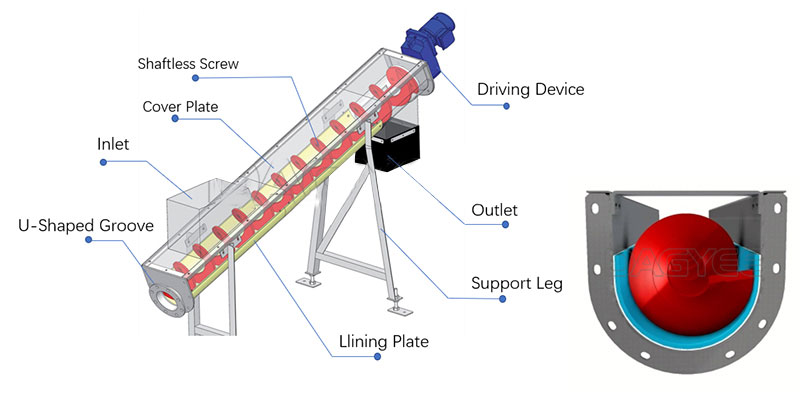

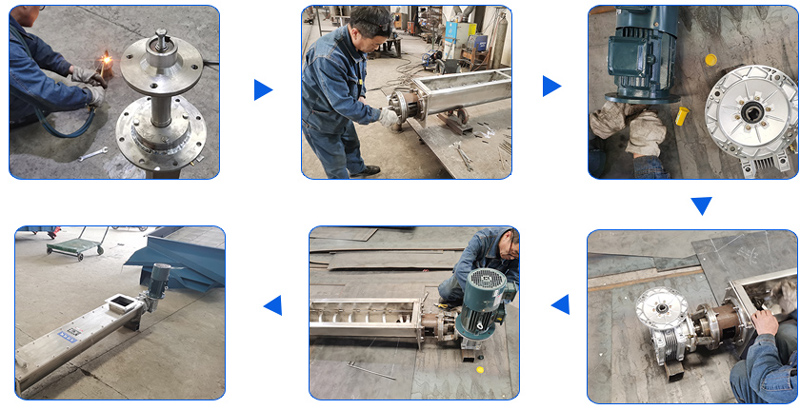

Structure of U-Shaped Screw Conveyor

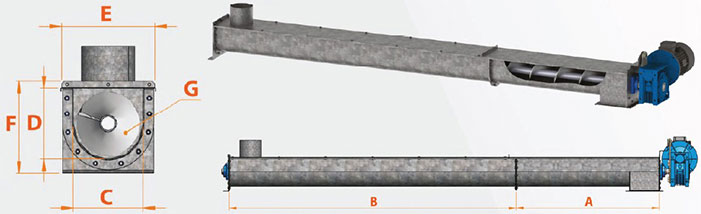

U-shaped screw conveyor consists of driving device, coupling, screw shaft, tank body, hanging bearing device, bearing device at both ends, support, cover, inlet and outlet, etc.

U-shaped screw conveyor has seven specifications: screw diameter: 150, 200, 250, 300, 400, 500, 600.

Ten standard revolutions (r/min): 20, 30, 35, 45, 60, 75, 90, 120, 150.

The length of the screw conveyor: from 3 meters to 20 meters, the length of the conveyor can be freely selected.

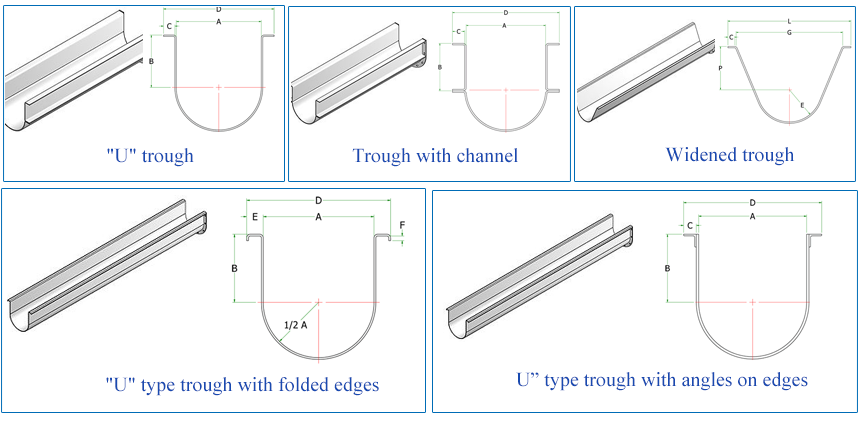

Troughs Types of U-Shaped Screw Conveyor

1. "U" trough: It is an economical trough, commonly used in screw conveyors. It is made from one single piece.

2.Trough with channel: increase rigidity when the channel is larger than the standard

3.Widened trough: use it when the material tends to "Puentearse" or the screw conveyor needs a wider entrance.

4."U" type trough with folded edges: A commonly used economical trough, made from a single piece. Additional folds provide rigidity to the piece.

5.U" type trough with angles on edges: rigid manufacturing.

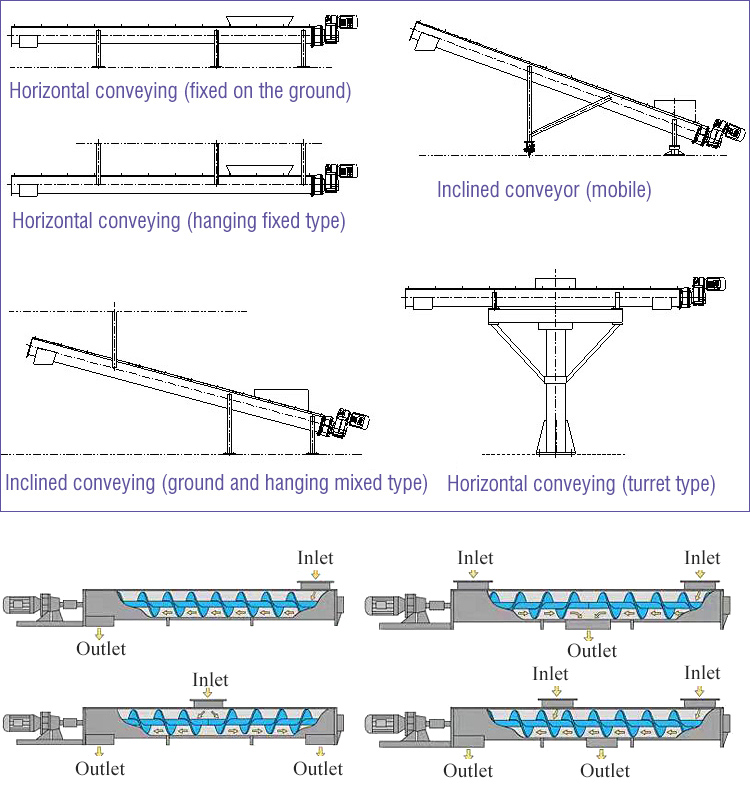

Layout of U-Shaped Screw Conveyor

U-shaped screw conveyors are normally ground-fixed. According to the needs, we can provide hanging type: ground, hanging mixed type; mobile type, rotary type and turret type that can be rotated around the axis of the feed port.

Application

U-Shaped Screw Conveyor conveys products horizontally/with a small inclination in a trough with a "U" cross-section, and is the preferred form of a shaftless conveyor. It can transport granular, powder and irregular materials including slurry, and can choose to add tank cover or open or semi-open design according to the actual conveying situation.

How To Choose The Right U-Shaped Screw Conveyor

1. Conveying material: powdery dry material, the specific gravity is not easy to be too heavy.

2. Installation angle: 0-15°

3. Conveying length: the larger the inclination angle is, the conveying length should not be too long.

4. Motor power: Determine the motor power to be selected according to the conveying length, inclination angle, conveying volume, etc., choose a large one or a small one.

5. Spiral speed: according to the specification and model and the inclination angle, the U-shaped screw conveyor speed is selected. The larger the inclination angle, the faster the speed.

In addition to regular models, our u-shaped screw conveyors also support model customization: