U Trough Screw Conveyor

It can handle throughputs up to 500 m³/h in a nominal size range of 150 to 600 mm.

Length: 10-20 meters

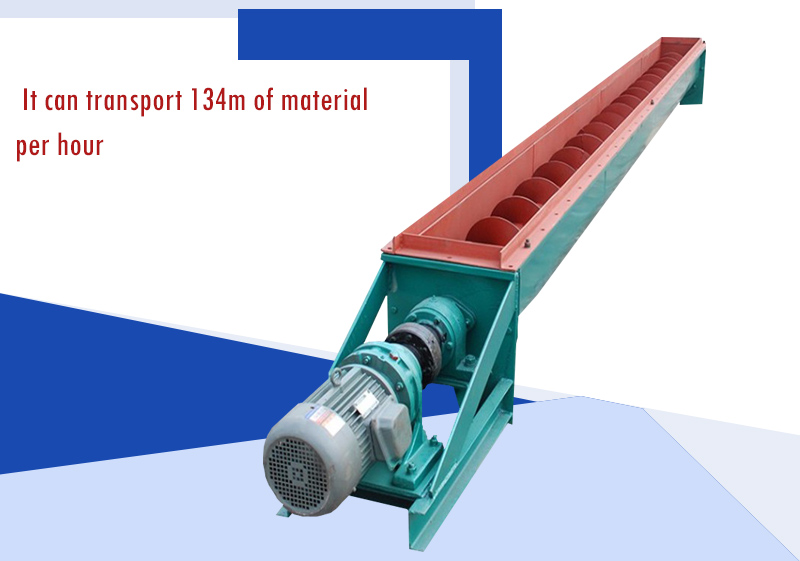

Output: 134 cubic meters per hour

Conveying angle: ≤25 degrees

U trough screw conveyors are suitable for free-flowing powders, granules and granules, as well as many materials with poor flow characteristics

Introduction of U Trough Screw Conveyor

U trough screw conveyor is a "u"-shaped trough, a lower screw assembly and a fixed installation structure. The u-trough is connected by segmented flanges, which is easy to replace and maintain the inner bushing. It is suitable for horizontal or small inclination conveying, inclined The angle does not exceed 25°, and it can be fed or discharged at a single point, and can also be fed or discharged at multiple points. It has great advantages for occasions with large dust and environmental requirements.

in addition. The upper part of the conveyor is equipped with a rain-proof cover, which has good sealing performance. The conveying process is basically closed transportation, which can effectively reduce the leakage of indoor odors or the entry of external dust.

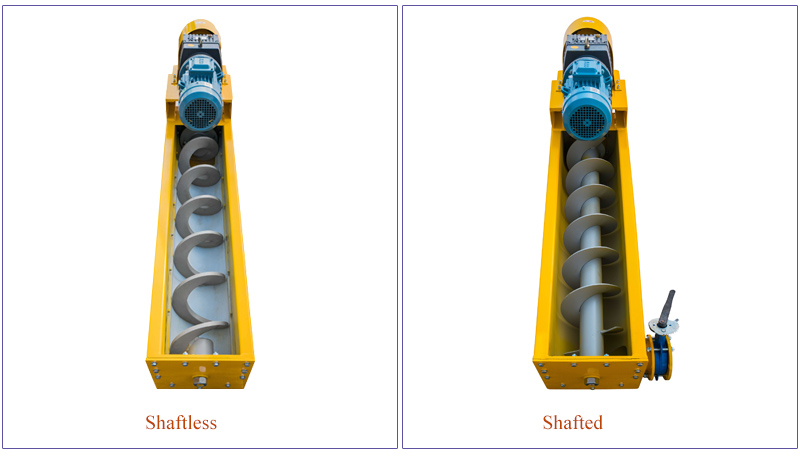

Types of U Trough Screw Conveyor

The conveying form is divided into two types: shafted and shaftless:

Shafted: suitable for non-viscous dry powder materials and small granular materials. (For example: cement, fly ash, lime, grain, etc.).

Shaftless: suitable for conveying viscous and easily entangled materials. (Example: sludge, biomass, garbage, etc.

Features and Benefits

1. The head and tail bearings are installed on the outside of the casing, with sliding bearings in the middle, and a dust-proof sealing device is designed to avoid the occurrence of dust when the material is conveyed, and will not pollute the environment too much, which is conducive to the later cleaning of hygiene; secondly, u trough The screw conveyor generally contains a removable cover, which is convenient for later maintenance and cleaning.

2. It can transport 134m of material per hour. There are single-axis driving screw and double-axis driving screw. The conveying capacity of double-spiral blade is larger than that of screw blade.

3. It can be loaded and unloaded at any point on its conveying line, and the intermediate feeding and unloading is convenient. Compared with other screw conveyors that cannot load and unload materials at any time, it has obvious advantages and can meet the needs of customers.

4. The suspension shaft and the screw shaft are connected by a slider. When disassembling the screw, there is no need to move the driving device. When disassembling the suspension bearing, there is no need to move the screw. The suspension bearing can be lubricated without removing the cover plate, which saves the replacement time of equipment accessories and has high equipment reliability. ,long lasting.

Technical Parameters

| Specification | Main technical performance | Drive | Drive | Weight(kg) | |||

| Diameter | length(m) | Yield t/h | Rotating speed(min) | Reducer | Electric motor | ||

| Model | Speed ratio | Power(kw) | |||||

| U 200 | -10 | 9 | 60 | ZQ250 | 23.34 | 1.1 | 726 |

| U 200 | -20 | 9 | 60 | ZQ250 | 23.34 | 1.5 | 1258 |

| U 250 | -10 | 15.6 | 60 | ZQ250 | 23.34 | 2.2 | 960 |

| U 250 | -20 | 15.6 | 60 | ZQ250 | 23.34 | 3 | 1750 |

| U 300 | -10 | 21.2 | 60 | ZQ350 | 23.34 | 3 | 1373 |

| U 300 | -20 | 21.2 | 60 | ZQ350 | 23.34 | 4 | 2346 |

| U 400 | -10 | 51 | 60 | ZQ400 | 23.34 | 5.5 | 1911 |

| U 400 | -20 | 51 | 60 | ZQ500 | 23.34 | 11 | 2049 |

| U 500 | -10 | 87.5 | 60 | ZQ400 | 23.34 | 7.5 | 2381 |

| U 500 | -20 | 87.5 | 60 | ZQ650 | 23.34 | 18.5 | 5389 |

| U 600 | -10 | 134.2 | 45 | ZQ750 | 23.34 | 22 | 3880 |

| U 600 | -10 | 134.2 | 45 | ZQ850 | 23.34 | 55 | 7090 |

The various types of u trough screw conveyors produced by Dahan Company are available. If you have special needs, we will design them free of charge according to your actual situation.

Structure of the Trough Screw Conveyor

u trough screw conveyor is mainly composed of driving device, head assembly, casing, screw body, trough lining plate, feeding port, discharging port, cover (when necessary), base and so on.

Design drawing of U-shaped screw conveyor

1. Driving device: Cycloidal pinwheel reducer or shaft-mounted hard-tooth surface gear reducer is used. In the design, the driving device should be set at the end of the discharge port as much as possible, so that the screw body is in a tension state during operation.

2. The head is equipped with a thrust bearing, which can bear the axial force generated when conveying materials.

3. Spiral blade: the general material is stainless steel or carbon steel. Considering the service life, it is recommended to use spiral conveyor blades made of high-strength wear-resistant steel.

4. Chassis: It is a "U"-shaped groove, with a rain-proof cover on the upper part, and the material is stainless steel or carbon steel or glass fiber reinforced plastic.

5. Tank body lining board: It is made of high-strength engineering plastic polymer polyethylene, which has weak adsorption, non-stick material, wear resistance and corrosion resistance.

6. Inlet and outlet: There are two kinds of square and round. Generally, the form of inlet and outlet is determined by the user.

Application

U trough screw conveyor is suitable for conveying powder, granular and small block materials with small inclination angle and small range. It is widely used in food, chemical, building materials, metallurgy, mining, electric power and other departments. The following are several common applications:

Sewage treatment plant: It can be used in sewage treatment plant to transport solid debris, such as coarse and fine grid cleaning machine slag and sludge cake of sludge dewatering machine. Waste treatment plant: kitchen waste or domestic waste generated by household kitchens, restaurants, restaurants, canteens, markets and other industries, stainless steel material can prevent damage to the machine due to corrosive materials.

Industrial waste treatment: such as boiler coal loading system, solid waste incineration, etc.

Cement batching plant: It is used for conveying powder materials such as cement and fly ash. During the conveying process, it can also realize the purpose of mixing and stirring the materials to prevent the concrete from agglomerating.

Solutions by Industry