Vertical Auger Conveyor

It is a mechanical conveying equipment used to transport bulk materials vertically. The distance between the inlet and outlet is 1-2.5 meters. It occupies a small area and is easy to maintain.

Height: ≤2.5 meters

Conveying capacity: 140 cubic meters/hour

Speed: 200-315 rpm

-

Introduction to Vertical Auger Conveyor

Vertical auger conveyor can lift all kinds of bulk materials on very steep slopes or completely vertical, and use the motor to drive the spiral rotation through the reducer, and through the rotation, the materials are transported to the predetermined position.

The feeding of the vertical auger conveyor must maintain the necessary feeding force. When the feeding level difference is small, the vertical screw conveyor is equipped with a horizontal feeding screw. Generally, the horizontal feeding screw and the vertical conveying screw are made into a whole. The diameter of the horizontal feeding screw is the same as that of the vertical screw, and the rotation speed of the horizontal feeding screw is lower than that of the vertical screw.

Types of Vertical Auger Conveyor

How does a vertical auger conveyor work?

The operation of a vertical auger conveyor can be broken down into the following steps:

Material is fed into the inlet of the conveyor, typically from a hopper or a feeder.

The rotating screw inside the conveyor tube moves the material upward, carrying it along the length of the screw.

As the material moves upward, it is compacted and compressed by the screw flights. This helps to prevent material from leaking or spilling out of the conveyor.

The material is discharged at the top of the conveyor, typically into a receiving hopper or another processing machine.

Features and Benefits

1. High-efficiency material transportation: It can transport materials efficiently and quickly over long distances. It is very suitable for applications that require vertical material transportation, and the vertical transportation height can reach 8 meters.

2. Gentle handling: materials can be handled gently, reducing the risk of damage and ensuring high-quality output. This is especially important for fragile materials such as food or pharmaceuticals.

3. Compact design: The compact design is very suitable for applications with limited space.

4. Easy installation: It can be easily installed and disassembled without special tools or equipment, reducing installation time and cost.

5. Low maintenance cost: simple design and minimal maintenance requirements, thus reducing downtime and maintenance costs.

How does a vertical auger conveyor compare to other types of screw conveyors?

The vertical auger conveyor is used to transport materials vertically. There are some differences in design and application compared to other types of auger conveyors such as horizontal or inclined auger conveyors. Here are some key differences:

Orientation: Vertical auger conveyors are used to convey materials vertically, while horizontal and inclined auger conveyors are designed to convey materials horizontally or inclined.

Capacity: Vertical auger conveyors typically have lower capacity than horizontal or inclined auger conveyors due to limitations in transporting materials vertically. However, they are still capable of handling a wide variety of materials and volumes in industrial and agricultural applications.

Material Handling: Vertical auger conveyors are ideal for handling materials that are difficult to transport using other types of auger conveyors, such as powders, granules, and other free-flowing materials. They are also ideal for delicate materials that require gentle handling, such as food or pharmaceuticals.

Space Requirements: The compact design requires less space than other types of auger conveyors. This makes them ideal for applications where space is limited, such as grain storage facilities or processing plants.

Video

Vertical auger conveyor for lifting feed

Vertical auger conveyor for lifting plastic pellets

Technical parameters

There are many types of vertical auger conveyor. If you have special needs, Dahan will provide you with customized services for free.

| Specification | LC160 | LC200 | LC250 | LC315 | |

| Diameter(mm) | 160 | 200 | 250 | 315 | |

| Rotating Speed(r/min) | 450 | 450 | 415 | 380 | |

| Capacity(m3/h) | 10 | 28.5 | 51 | 95 | |

| Conveying Height(m) | 2.5~15 | 2.5~15 | 2.5~15 | 2.5~15 | |

| Motor | Height(m) | 2.5~5.5 | 2.5~5.5 | 2.5~4 | 2.5~4 |

| Model | Y100L2-4 | Y100L2-4 | Y132M1-6 | Y160M-6 | |

| Power | 3KW | 3KW | 4KW | 7.5KW | |

| Height(m) | 6~7 | 6~7 | 4.5~5.6 | 4.5~6 | |

| Model | Y112M-4 | Y112M-4 | Y132M2-6 | Y160L-6 | |

| Power | 4KW | 4KW | 5.5KW | 11KW | |

| Height(m) | 7.5~10 | 7.5~10 | 6~7.5 | 6.5~8 | |

| Model | Y132S-4 | Y132S-4 | Y160L-6 | Y160L-6 | |

| Power | 5.5KW | 5.5KW | 7.5KW | 15KW | |

| Height(m) | 10.5~13.5 | 10.5~13.5 | 8~11 | 8.5~12 | |

| Model | Y132S-4 | Y132M-4 | Y160L-6 | Y180L-6 | |

| Power | 7.5KW | 7.5KW | 11KW | 11KW2台 | |

| Height(m) | 14~15 | 14~15 | 11.5~15 | 12.5~15 | |

| Model | Y160M-4 | Y160M-4 | Y180L-6 | Y180L-6 | |

| Power | 11KW | 11KW | 15KW | 15KW2台 | |

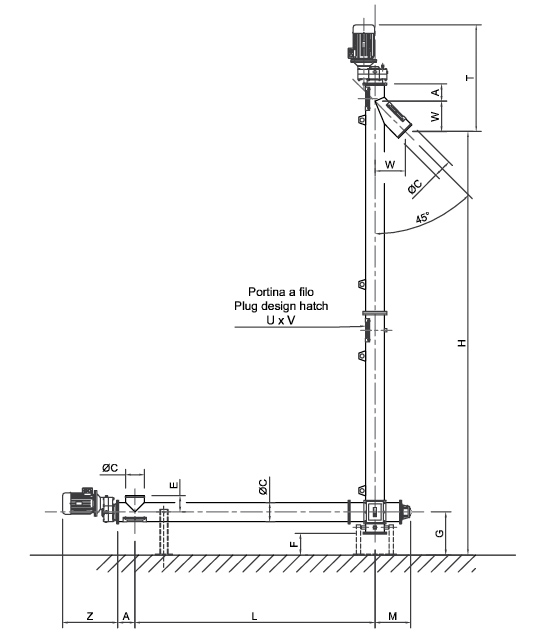

Structure of the Vertical Auger Conveyor

The vertical screw lifting system consists of a horizontal auger conveyor and a vertical screw conveyor.

Horizontal helical auger conveyors are fed from silos or hoppers or fed by upstream feeding units and consist of U-shaped or tubular carbon steel troughs with suitable surface treatment. The outlet area of the horizontal screw feeder consists of a short pipe section which is tangentially flanged at a right angle at the bottom of the vertical screw conveyor. Both ends of the horizontal screw feeder are welded with flanges. The trough or tube contains a rotating screw with connecting bushings at each end to the shaft of the bearing assemblies at both ends. Horizontal screw feeders are equipped with one or more intermediate suspension bearings, if required for their overall length. In addition, the horizontal screw feeder is equipped with an application-appropriate drive unit.

The vertical auger conveyor consists of a tubular casing with the above-mentioned tangential inlet at the bottom, which is connected to the outlet of the horizontal screw feeder, and a sloping outlet at the top. Rotating threaded rods in , with coupling bushings on each end, base bearing assemblies with sliding bushings, and some intermediate hanger bearings (if required for the overall height of the conveyor). A top mounted drive unit with an integrated end bearing assembly on which the screw hangs and a self-adjusting shaft seal is suitable for this application.

Available Options

Here are some examples of customizable options for vertical auger conveyors:

Hopper: The top of the vertical auger conveyor can be equipped with a hopper to provide storage space for materials before vertical transportation. Hoppers can be designed in a variety of capacities and materials of construction to meet specific material handling requirements.

Discharge chute: A discharge chute can be added to the bottom of the auger conveyor to direct material to a specific location or process. The discharge chute can be customized in various lengths and angles to suit specific applications.

Flexible Connections: Flexible connections can be added at the inlet and outlet of a vertical auger conveyor to provide a seal between the conveyor and other equipment. This helps prevent material leakage and ensures efficient material flow.

Variable speed drive: A variable speed drive can be added to the motor of the vertical auger conveyor to control the speed of the screw and optimize the material flow. This allows for greater flexibility in material handling and helps reduce wear and tear on the conveyor.

Materials of Construction: Can be customized in a variety of materials of construction to suit specific applications. For example, stainless steel can be used in food-grade applications, while carbon steel can be used in industrial applications.

Dust control system: A dust control system can be installed to minimize dust emissions during material transportation. This helps improve air quality and reduces the risk of fire or explosion in some applications.

Vertical Auger Conveyor horsepower calculation formula:

1. The horsepower required to drive the Vertical Auger Conveyor with no load

HPf=(L*N*Fd*Fb)/1000000

2. The horsepower required to push the conveying material:

HPv=(Cw*L*Fv)/1000000 or HPv=(Cv*W**L*Fv)/1000000

3. Total shaft horsepower:

HPt=[(HPf+HPv+Fi)*Fo]/e

| Symbol meaning: | |||

| L | Vertical Lift Height | N | Conveyor Speed |

| Fd | Diameter Factor | Fb | Bushing Factor |

| Cw | Conveyor Capacity (Pounds per Hour) | Cv | Conveyor Capacity (Cubic Feet per Hour) |

| W | Density (Pounds per Cubic Foot) | Fv | Material Horsepower Factor (From Materials Table) |

| Fi | Incline Factor | e | Motor Efficiency |

| Fo | Overload Factor (Correction for calculated horsepowers of less than five horsepower) | ||

| The above are the calculation formulas under ideal conditions, and the specific design is based on the actual suggestions given by Dahan Machinery. | |||

Average Capacities and Speeds of Vertical Auger Conveyor

| Nominal diameter of screw in (mm) | Capacities in (m3/hr) | Speed of screw |

| 150 | 10 | Up to 400 RPM |

| 250 | 35 | 300 RPM |

| 300 | 75 | 250 RPM |

| 400 | 170 | 200 RPM |

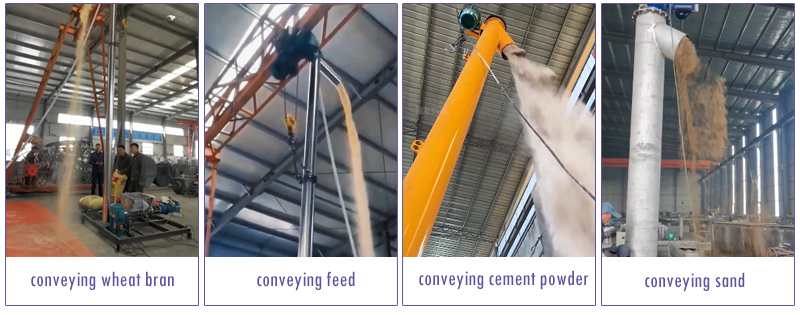

Application

Vertical auger conveyors are used in various industries such as agriculture, food processing, pharmaceuticals, chemical processing, and mining for transporting a wide range of materials including grains, powders, pellets, and granular materials.

1.Agriculture: Vertical auger conveyors are widely used in the agricultural sector for handling grains, seeds, and other agricultural products. They are used in grain elevators, silos, and storage facilities to move crops vertically for storage, loading, or unloading.

2.Food Processing: In the food industry, vertical auger conveyors are utilized for transferring food products such as powders, granules, and flakes. They are commonly used in processing plants for conveying ingredients, such as flour, sugar, spices, and additives, to mixers, packaging machines, or storage bins.

3.Chemical Processing: Vertical auger conveyors are employed in chemical processing plants to handle various bulk materials, including powders, pellets, and chemicals. They are utilized for transferring materials between different processing stages, such as mixing, drying, blending, and packaging.

4.Construction: Vertical auger conveyors are utilized in the construction industry for handling materials like cement, sand, and aggregates. They can be employed in concrete batching plants and construction sites to lift and transfer materials to different levels, such as from ground level to elevated storage bins or mixing equipment.

Solutions by Industry

Vertical Auger Conveyor can be used in the lifting application of grain or feed, food, chemical and other products. Its compact structure only requires the smallest space area, and is suitable for most factory layout. Suitable for conveying bulk materials with fluidity or plate fluidity.

-

Vertical Auger Conveyor for feeding the silo

-

Vertical Auger Conveyor with belt conveyor for food processing plants

-

Vertical Auger Conveyor with U-shaped screw conveyor to process peanut shells

| Factory | Application |

| foundry | Sand treatment, lime conveying |

| brewery | Grain and Hops Handling/Storage |

| wooden product | waste and sawdust |

| Paper | Pulp and Wood Chip Handling |

| chemical plant | chemical powder |

| Feed and Grain | Raw materials are transported to the lower end equipment |

| food factory | Involvement in the food processing process |

| materials | Lifting height (meters) |

Conveying capacity (t/h) |

model |

| Sand | 6 | 6 | LC273 |

| Iron oxide | 7 | 1 | LC219 |

| coffee powder | 4 | 1 | LC159 |

| Soybeans | 5 | 5 | LC160 |

| Aluminum block | 4 | 1 | LC245 |

| salt | 1.5 | 5 | LC219 |

| catalyst | 4 | 10 | LC315 |

What matters need to be considered when installing vertical auger conveyor?

1.) Bulk Size - Materials with widely varying particle sizes, or bulky materials that are too large often cannot be conveyed properly in the vertical screw. Generally, free-flowing materials that do not degrade will work fine in vertical screws. Fragile materials, as well as aerated, very fine powders often do not work well in vertical screws.

2.) Very dense materials - Due to the full load conditions and speeds of vertical screw operation, very dense materials with little or no compressibility may not be conveyed properly.

3.) Abrasive material - Due to the high speed and full contact of the material with the screw, abrasive material can rapidly degrade components, as well as prematurely worn seals and drive components.

Explore more vertical lifting equipment

It is suitable for large-volume granular, block, irregular or fragile bulk materials, with a small footprint and a large height lift of 40 meters. There are various forms.

The simplest lifting equipment, 30°-90° inclined vertical conveying, with minimal budget, for transporting parcels, granules or bulk products, the conveying capacity decreases with the increase of slope.