Magnetic Vibrating Feeder For Packing

For temporary storage of dry, free-flowing food and non-food products to packaging machines

Applications: for dosing, for granulates

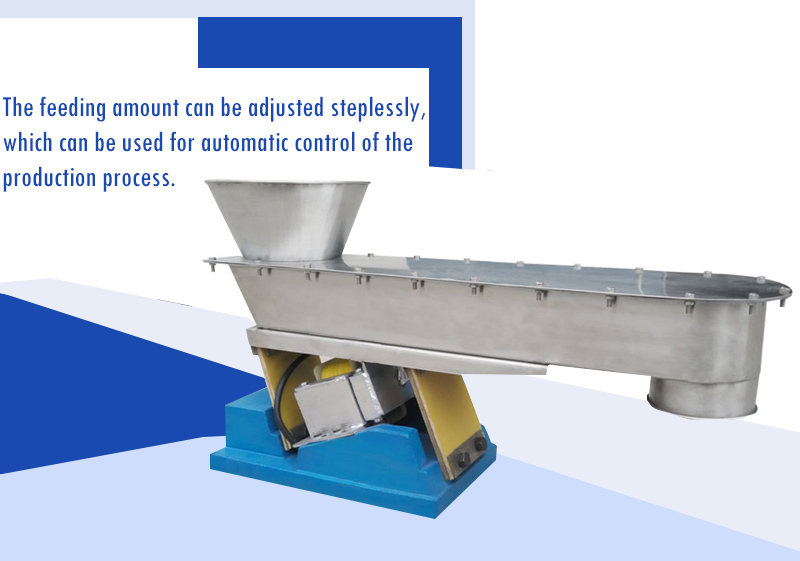

Feed system: with vibrating feeder

Other characteristics: stainless steel

Introduction of Magnetic Vibrating Feeder For Packing

The Magnetic vibrating feder for packing is used with feeding, weighing and metering functions and is a self-discharging bulk hopper capable of storing and then discharging components or materials in a controlled continuous flow. Vibratory feeders are primarily suitable for machinery or products that mesh or do not feed well from static hoppers, eliminating many of the production interruptions that can occur with more traditional systems. Magnetic vibrating feder for packing can measure flowing material and can also control or regulate flow by changing speed.

Application

The Magnetic Vibrating Feeder's integrated load cells and console allow for dosing and continuous feeding of bulk materials according to the specified weight, and the feeding trough can be specially designed, such as adding meshes, changing shapes, etc., as required.

It can transport potato chips and biscuits, transport coffee raw materials to the packaging machine and remove foreign objects, and feed the quantitative cocoa powder into the packaging machine, etc. Can be used in food, medicine, ceramics, automobile, chemical, recycling and other industries

Application demonstration video

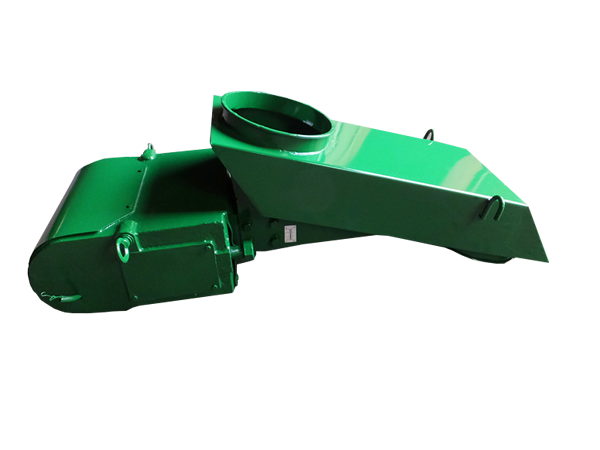

Cylindrical Magnetic Vibrating Feeder for Biscuit Packaging

Dual hopper Magnetic Vibrating Feeder for floc packaging

Features and Benefits

1. The effective discharge port of the silo material shall not be larger than a quarter of the groove width, and the flow speed of the material shall be controlled at 6-18m/min.

2. The material is micro-throwing motion, and the trough wear is small.

3. The feeding amount can be adjusted steplessly, which can be used for automatic control of the production process.

4. Automatically cut off the silo unloading when the machine is stopped.

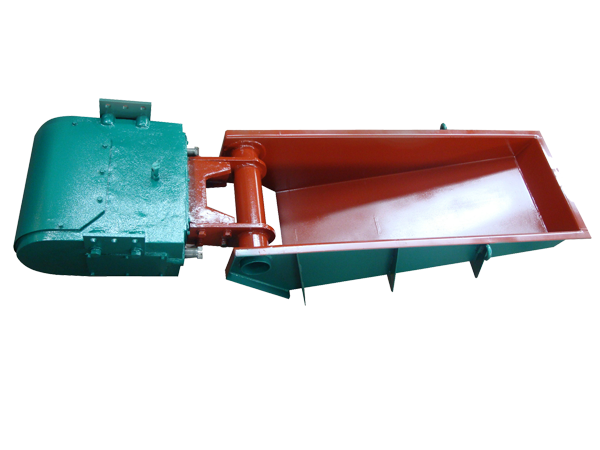

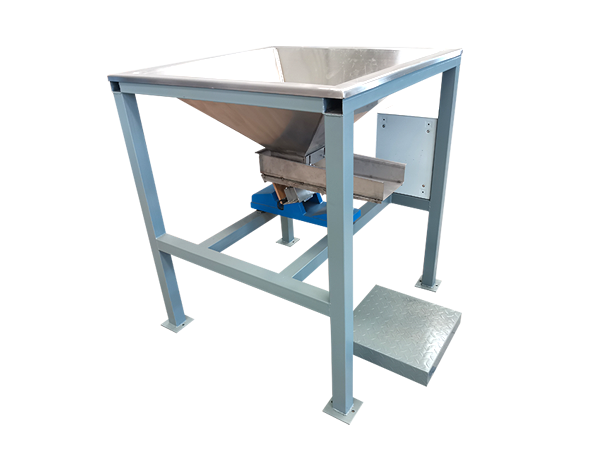

Structure of Magnetic Vibrating Feeder For Packing

Magnetic vibrating feder for packing consists of a vibrating storage feeder, a vibrating feeder, a chute system with accumulation possibility, a workbench with integrated load cells and an integrated sample/check weighing platform. It's all controlled by PLC. It can be configured in different sizes and is equipped with lifts and tip devices. The lift dump truck is configured according to the customer's specific container/container.

Technical Parameters

| Model |

Feeding amount (t) |

power (kw) |

Voltage (V) |

Vibration frequency (t/min) |

Amplitude (Mm) |

Dimensions |

| ZG-15 | 15 | 2×0.12 | 380 | 1500 | 2-3 | 1000×380×510 |

| ZG-30 | 30 | 2×0.18 | 2-3 | 1100×480×560 | ||

| ZG-50 | 50 | 2×0.25 | 2-3 | 1100×580×630 | ||

| ZG-100 | 100 | 2×0.55 | 2-5 | 1200×800×780 | ||

| ZG-200 | 200 | 2×0.75 | 2-5 | 1350×1060×850 | ||

| ZG-300 | 300 | 2×1.1 | 3-5 | 1350×1100×950 | ||

| ZG-500 | 500 | 2×1.5 | 4-6 | 1600×1250×1000 | ||

| ZG-750 | 750 | 2×2.2 | 1000 | 4-6 | 1840×1560×1050 |

Solutions by Industry

Magnetic Vibrating Feeder with other equipment to feed bulk material into packaging machine

-

Multiple Magnetic Vibrating Feeders work together

Mixed Vegetable Dried Production Line

-

Magnetic Vibrating Feeder with packing machine

Popcorn Production Line

-

Magnetic Vibrating Feeder with Furnace

metal smelting

-

Magnetic Vibrating Feeder with Z Type Bucket Elevator

Material: Grain

-

Magnetic Vibrating Feeder with packaging machine

Material: Nuts Almonds

-

Magnetic Vibrating Feeder with linear vibrating sieve

Material:ceramic particles