Micro Vibrating Feeder

In the production process of feeding, batching and quantitative automatic packaging of powdery and granular materials, it can realize centralized control and automatic control, the feeding speed and feeding amount can be adjusted, and the feeding accuracy is high.

Vibration frequency: 3000 times/min

Amplitude: 1.5mm

Feeding particle size: 0.6-500mm

Material flow speed: 6-18m/min

Conveying capacity: 10kg/h

Weight: 4kg

Introduction of Micro Vibrating Feeder

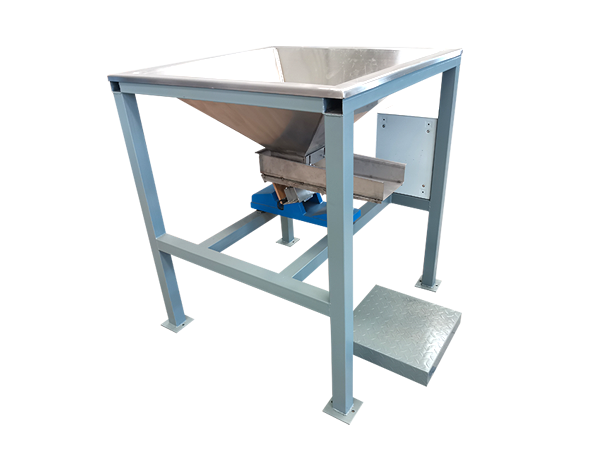

The volume of the micro vibrating feeder in the equipment for transporting materials is relatively small, but although the volume is small, the function is satisfactory. It can be used in the transportation of a small amount of materials to avoid the problem of increasing the cost of using large equipment.

Micro vibrating is used in the production process of feeding, batching and quantitative automatic packaging of powdery and granular materials, and can realize centralized control and automatic control, realize automatic work, and reduce a lot of repetitive labor.

Types of Micro Vibrating Feeder

1. Different materials

Carbon steel: Q235 carbon steel trough is used, which is suitable for customers with low hygiene requirements, and the price is cheap.

Stainless steel: It is made of SUS304 stainless steel trough, which is resistant to corrosion, high temperature, not easy to rust, and can avoid the pollution of raw materials.

2. Different structures

Open type: It is a common structure. Suitable for material feeding without special requirements.

Enclosed Type: The closed type micro vibrating feeder has a closed body design to prevent dust contamination. It is suitable for feeding materials with fragile particles, large dust and easy volatilization.

Features and Benefits

1. Small size, light weight, simple structure, easy installation and low operating cost.

2. Due to the use of the mechanical vibration resonance principle, the power consumption is small.

3. The thyristor half-wave rectifier is used for power supply, and the feeding amount can be adjusted steplessly during use.

4. The feeder continuously throws up the material during the feeding process, so the wear of the feeding trough is small.

5. The material trough made of alloy steel plate is suitable for conveying high temperature, severe wear and corrosive materials.

Technical parameters

| Types of | Model | Productivity(t/h) | Feed particle sizemm | Double amplitudemm | Voltage(V) | Current(A) | Power(Kw) | Matching control box | ||

| level | -10 degrees | Working current | Indicates current | |||||||

| Basic | GZ1 | 5 | 7 | 50 | 1.75 | 220 | 1.34 | 1 | 0.06 | XKZ-5G2 |

| GZ2 | 10 | 14 | 50 | 3.0 | 2.3 | 0.15 | ||||

| GZ3 | 25 | 35 | 75 | 4.58 | 3.8 | 0.2 | ||||

| GZ4 | 50 | 70 | 100 | 8.4 | 7 | 0.45 | XKZ-20G2 | |||

| GZ5 | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | ||||

| GZ6 | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 13.3 | 1.2 | XKZ-20G3 | |

| GZ7 | 250 | 350 | 250 | 24.6 | 20 | 3 | ||||

| GZ8 | 400 | 560 | 300 | 39.4 | 32 | 4 | ||||

| GZ9 | 600 | 840 | 350 | 47.6 | 38.6 | 5.5 | XKZ-200G3 | |||

| GZ10 | 750 | 1050 | 500 | 39.4*2 | 32*2 | 4*2 | XKZS-200G3 | |||

| GZ11 | 1000 | 1400 | 500 | 47.6*2 | 38.6*2 | 5.5*2 | ||||

| Up mode | GZ3S | 25 | 35 | 75 | 1.75 | 220 | 4.58 | 3.8 | 0.2 | XKZ-5G2 |

| GZ4S | 50 | 70 | 100 | 8.4 | 7 | 0.45 | XKZ-20G2 | |||

| GZ5S | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | ||||

| GZ6S | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | XKZ-20G3 | |

| GZ7S | 250 | 350 | 250 | 24.6 | 0 | 3 | XKZ-100G3 | |||

| GZ8S | 400 | 560 | 300 | 39.4 | 32 | 4 | ||||

| Closed | GZ1F | 4 | 5.6 | 40 | 1.75 | 220 | 1.34 | 1 | 0.06 | XKZ-5G2 |

| GZ2F | 8 | 11.2 | 40 | 3 | 2.3 | 0.15 | ||||

| GZ3F | 20 | 28 | 60 | 4.58 | 3.8 | 0.2 | ||||

| GZ4F | 40 | 56 | 60 | 8.4 | 7 | 0.45 | XKZ-20G2 | |||

| GZ5F | 80 | 112 | 80 | 12.7 | 10.6 | 0.65 | ||||

| GZ6F | 120 | 168 | 80 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | XKZ-20G3 | |

| light groove | GZ5Q | 100 | 140 | 200 | 1.5 | 220 | 12.7 | 10.6 | 0.65 | XKZ-20G2 |

| GZ6Q | 150 | 210 | 250 | 380 | 16.4 | 13.3 | 1.5 | XKZ-20G3 | ||

| GZ7Q | 250 | 350 | 300 | 24.6 | 20 | 3 | XKZ-100G3 | |||

| GZ8Q | 400 | 560 | 350 | 39.4 | 32 | 4 | XKZ-100G3 | |||

| Flat groove | GZ5P | 50 | 70 | 100 | 1.5 | 220 | 12.7 | 10.6 | 0.65 | XKZ-20G2 |

| GZ7P | 75 | 105 | 380 | 16.4 | 13.3 | 1.5 | XKZ-20G3 | |||

| GZ7P | 158 | 175 | 24.6 | 20 | 3 | XKZ-100G3 | ||||

| Wide groove | GZ5K1 | 240 | 100 | 1.5 | 220 | 12.7*2 | 10.6*2 | 0.65*2 | XKZ-20G2 | |

| GZ5K2 | 240 | |||||||||

| GZ5K3 | 270 | |||||||||

| GZ5K4 | 300 | |||||||||

| Round tube | GZ1G | 2 | 50 | 1.75 | 220 | 1.34 | 1 | 0.06 | XKZ-5G2 | |

| GZ2G | 4 | 50 | 3.0 | 2.3 | 0.15 | XKZ-5G2 | ||||

| GZ3G | 10 | 60 | 4.58 | 3.8 | 0.2 | XKZ-5G2 | ||||

| GZ4G | 20 | 70 | 8.4 | 7 | 0.45 | XKZ-20G2 | ||||

| GZ5G | 40 | 80 | 12.7 | 10.6 | 0.65 | XKZ-20G2 | ||||

| Extra large | GZ11-T | 100 materials are coal with a specific gravity of 0.85 | 300 | 1.5 | 380 | 47.6*2 | 38.6*2 | 5.5*2 | SZK.00 | |

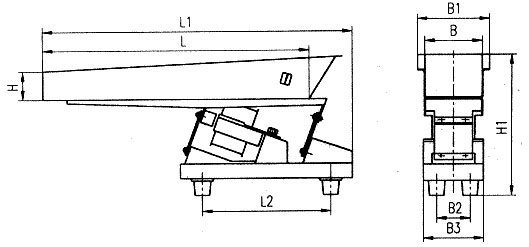

Micro Vibrating Feeder Dimensions

| Model | B | B1 | B2 | B3 | L | L1 | L2 | H | H1 | H2 |

| GZV1 | 40 | 60 | 50 | 80 | 200 | 273 | 95 | 20 | 155 | 120 |

| GZV2 | 60 | 80 | 50 | 80 | 300 | 374 | 95 | 30 | 168 | 120 |

| GZV3 | 80 | 110 | 60 | 100 | 400 | 480 | 224 | 40 | 222 | 160 |

| GZV4 | 100 | 130 | 70 | 120 | 500 | 568 | 310 | 50 | 256 | 190 |

| GZV5 | 120 | 150 | 70 | 120 | 550 | 630 | 310 | 60 | 295 | 190 |

| GZV6 | 200 | 240 | 120 | 180 | 600 | 760 | 440 | 70 | 300 | 220 |

| Note: The feeding trough can be modified into closed, lengthened, widened or other forms according to actual needs. | ||||||||||

Viedo

food powder micro vibrating feeder

Micro vibrating feeder feeding bin

Application

Micro vibrating feeder is widely used in food, grain, experiment, chemical industry, medicine, grinding, light industry, food processing, commercial and other industries, and is used for feeding, batching and quantitative automatic packaging of powdery and granular materials. It can realize centralized control and automatic control.

Chemical industry: plastic granules, rubber powder, PVC granules

Abrasive industry: quartz sand, zirconium corundum, silicon carbide

Pharmaceutical industry: tablets, pharmaceutical powder, pharmaceutical granules

Food industry: rock candy, potato chips, cocoa beans

The Micro Vibrating Feeder can also be used in conjunction with conveying, lifting and packaging equipment in the production line, enabling accurate, rapid and continuous feeding and saving a lot of labor costs.

-

Micro Vibrating Feeder with Z Type Bucket Elevator

Material: Grain

-

Micro Vibrating Feeder with packaging machine

Material: Nuts Almonds

-

Micro Vibrating Feeder with linear vibrating sieve

Material:ceramic particles

Solutions by Industry

-

Micro Vibrating Feeder used in machinery parts factory

-

Micro Vibrating Feeder used in food processing plants

-

Micro Vibrating Feeder used in confectionery production plant

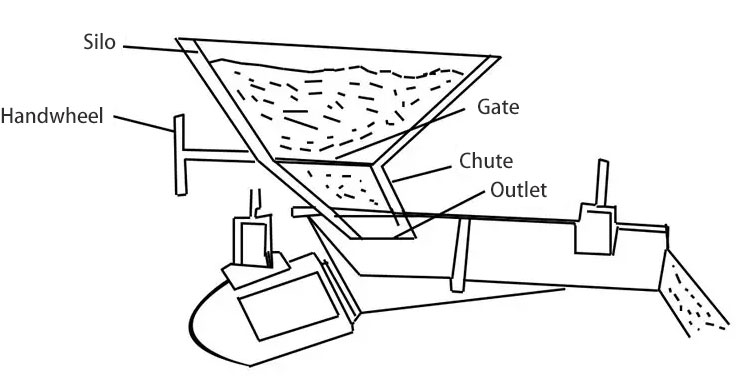

Silo design and feeder installation

1. The design of this series of micro vibrating feeders does not consider the influence of silo pressure. In order to ensure the normal operation of the feeder, the following points should be paid attention to when configuring the silo:

(1) There should be a gap of about 5 mm between the outlet of the silo and the feeding trough to ensure that the trough is not affected by the silo during the vibration process.

(2) The outlet of the silo should be designed with an inclined sliding nozzle to prevent the vertical pressure of the material column from directly pressing on the feeder, otherwise it will seriously affect the efficiency of the feeder.

(3) The size of the opening of the silo should be able to ensure sufficient material layer thickness. At the same time, a gate should be set in order to adjust the thickness of the material layer.

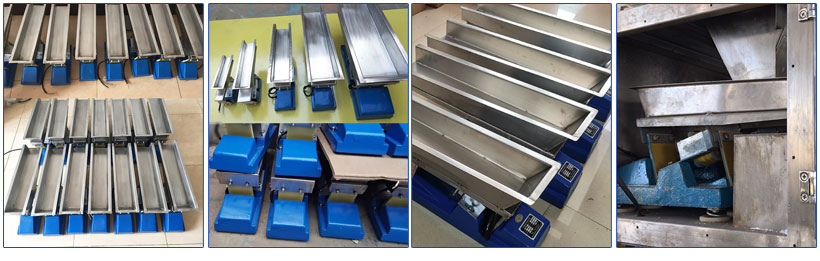

Factory picture display