Weighing Machine with Vibratory Feeder

Used in bulk material feeding, weighing and packaging applications, it provides easy and continuously adjustable flow control and near-instantaneous stop-start material flow.

Type:electronic

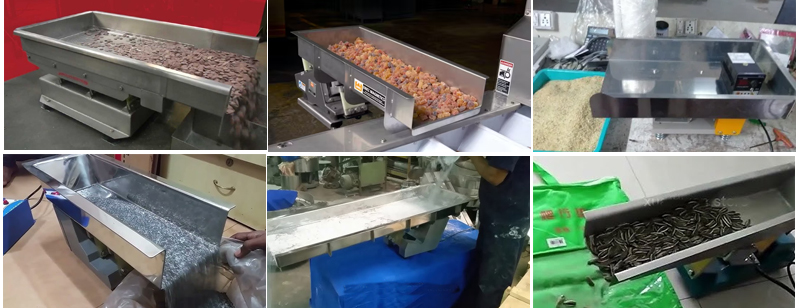

Applications: for dosing, for granulates

Feed system:with vibrating feeder

Other characteristics:stainless steel

Introduction of Weighing Machine with Vibratory Feeder

Weighing machine with vibratory feeder is an indispensable and important part of the automatic powder batching and weighing system. It is generally installed at the discharge port of the storage silo. Relying on the gravity of the powder and the forced action of the feeding mechanism, the storage material is stored. The powder in the silo is discharged and continuously and evenly conveyed to the weighing equipment.

It stops immediately after filling close to the set weight, and then the material slowly drips out until it reaches the set weight, the speed of bulk feeding can improve the filling efficiency, and the drip feeding can strictly control the material. This allows for the most accurate filling and packaging without slowing down production. The electromagnetic drive allows the feed rate to be fully adjusted and set to suit a specific application or line, and the feeder does it all automatically, making it ideal for weighing and packaging applications.

What Is Weighing Machine with Vibratory Feeder Used For?

By combining the weighing function and the vibratory feeding function, the combination of the weighing machine and the vibratory feeder can achieve efficient and accurate material weighing and feeding, which is suitable for various production environments where the material dosage needs to be accurately controlled.

1. Feeding function: Vibratory feeder is used to provide continuous and stable material supply, prevent material blockage, and ensure that the material enters the weighing system at a uniform rate.

2. Weighing function: This equipment is mainly used to accurately weigh materials. Through the weighing system, the weight of the material can be accurately measured and recorded to ensure that the quantity of material in each batch meets the predetermined requirements.

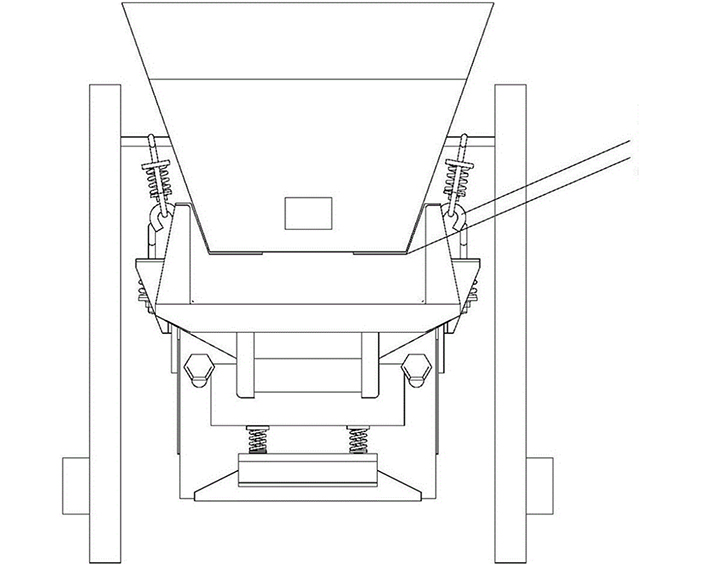

Weighing Machine with Vibratory Feeder Working Principle

The working principle of the weighing machine with vibratory feeder includes the following steps:

Material delivery: The material enters the feed trough through the upper feed port.

Vibration conveying: The vibration device is started, and the vibration generated causes the material to move forward in the feed trough.

Weighing monitoring: The weighing sensor monitors the weight of the material in the feed trough in real time and transmits the data to the control system.

Data feedback: The control system automatically adjusts the vibration frequency and amplitude according to the information fed back by the weighing sensor to ensure that the material feeding amount meets the set value.

Material unloading: The material is evenly discharged through the lower discharge port and sent to the subsequent process.

Features and Benefits

1.Loads cells accurately weigh the product as it is discharged over the process machine.

2.Pneumatically actuated gates control product flow.

3. Panel mounted PLC controls both vacuum or pressure line interface capabilities.

4. Sanitary stainless steel construction reduces cleaning time for the food and beverage industry.

5. Feeder eliminates any uneven disruption in product flow.

6. When the weight reaches the set value, the material flow stops almost immediately.

Videos

Technical parameters

| Model | GZV1 | GZV2 | GZV3 | GZV4 | GZV5 | |

| Capacity (tons/hour)5 | 0.1 | 0.5 | 1 | 2 | 4 | |

| Double amplitude (mm) | 1.5 | |||||

|

Frequency (times/minute) |

3000 | |||||

| Power (W) | 5 | 8 | 20 | 25 | 30 | |

| Control equipment | Model | Model:XKZV-Ⅱ | ||||

| Control method | Controlled Half-Wave Rectifier | |||||

|

Tension (V) |

220 | |||||

|

Frequency (Hz) |

50 | |||||

|

Current (A) |

0.08 | 0.12 | 0.15 | 0.2 | 0.25 | |

| Weight | 4 | 7 | 12 | 18 | 27 | |

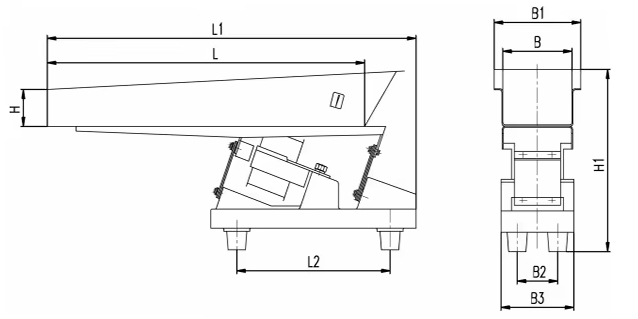

Dimensions of Weighing Machine with Vibratory Feeder

| Model | B | B1 | B2 | B3 | L | L1 | L2 | H | H1 |

| GZV1 | 40 | 60 | 50 | 80 | 200 | 273 | 95 | 20 | 170 |

| GZV2 | 60 | 80 | 80 | 300 | 300 | 374 | 100 | 30 | 190 |

| GZV3 | 80 | 110 | 75 | 106 | 400 | 480 | 224 | 40 | 230 |

| GZV4 | 100 | 130 | 80 | 120 | 500 | 568 | 295 | 50 | 260 |

| GZV5 | 120 | 150 | 95 | 130 | 550 | 630 | 330 | 60 | 270 |

| GZV6 | 200 | 240 | 120 | 180 | 600 | 760 | 440 | 70 | 320 |

| GZV8 | 300 | 3400 | 180 | 230 | 1000 | 1050 | 560 | 70 | 340 |

Application

A common use of a Weighing machine with vibratory feeder is in filling applications where the electromagnetic drive operates at maximum amplitude to quickly fill a weighing container, when the target weight is reached, the feed speed is slowed to a trickle until the final weight is reached and the equipment is stopped. Vibratory feeders can also be used to meter product into elevators, pneumatic conveyor lines or belt conveyors, and discharge from silos, hoppers, bulk bag stations or silos.

Weighing machine with vibratory feeder can provide efficient and accurate material conveying and metering in multiple industries to ensure the stability of the production process and product quality. , including the following occasions:

1. Mining: used to accurately control the conveying of bulk materials such as ore and coal to ensure the stable operation of the production line.

2. Chemical raw material batching: used to convey and meter various chemical raw materials such as powder, granules and liquid additives.

3. Catalyst conveying: in the chemical reaction process, accurately control the amount of catalyst added.

3. Food additive delivery: accurately control the amount of food additives added to meet the formulation requirements.

4. Pharmaceutical ingredient metering: in the pharmaceutical process, accurately control the delivery of pharmaceutical ingredients to ensure product consistency and quality.

5. Cement and aggregate conveying: used for the conveying of building materials such as cement, sand and gravel to ensure the accuracy of the mixing ratio.

6. Plastic granule conveying: used to convey plastic granules to ensure the efficient operation of the production line.

Solutions by Industry